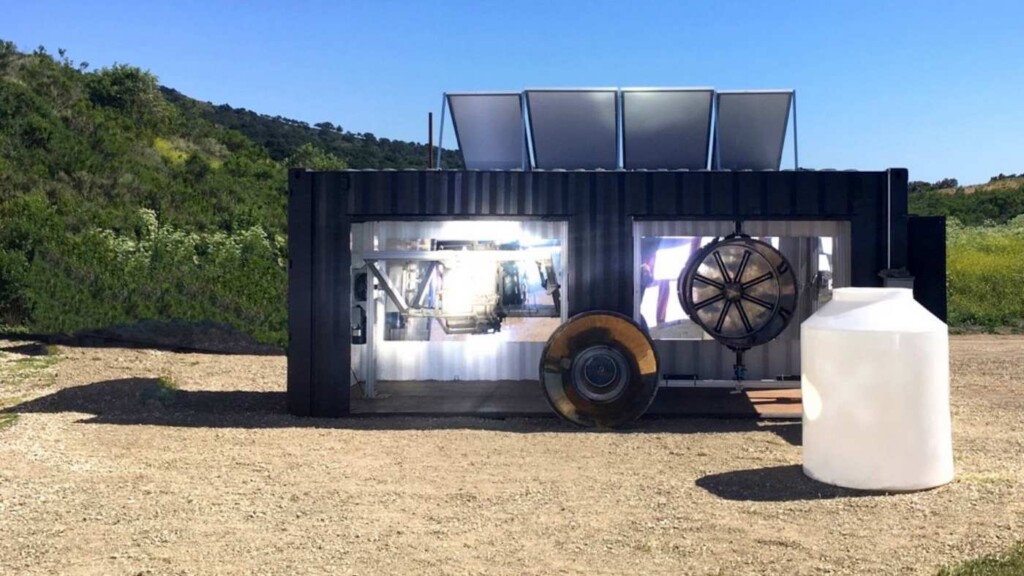

A startup has discovered a method to create high-quality plastic merchandise like water tanks, boat frames, and extra, all utilizing the ability of the solar, and has created a conveyable manufacturing unit that may be transported wherever on the earth through transport containers.

The pace and adaptability of the manufacturing unit system make it an unbelievable asset for companies or governments working in quite a few environments and conditions from catastrophe aid to rural growth.

Known as Gentle Manufacturing, the expertise is named Photo voltaic Rotational Molding (SRM), and in layman’s phrases entails placing uncooked plastic right into a mould and blasting it with a beam of daylight concentrated through a financial institution of 30 particular mirrors known as heliostats that routinely modify to maintain shining on the mould because the solar strikes throughout the sky.

Karl von Kries, founding father of Gentle Manufacturing and inventor of SRM, used to work for a Massachusettes-based firm that used rotational molding for flight instances, and began on his entrepreneurial journey after seeing the corporate’s vitality payments, and watching An Inconvenient Reality.

“Again then I discovered it unusual that we have been paying for lots of pure gasoline, however in the summertime months, the roof of the manufacturing unit was properly over 130 levels Fahrenheit,” he instructed GNN. “I questioned if there was some method to seize that photo voltaic warmth.”

“I assumed that this concept had been tried earlier than, and was discovered impractical. However I couldn’t discover something within the literature about photo voltaic rotational molding, so I arrange a brand new firm to ‘show the concept would NOT work’ so I may get on with my profession.”

Then a wierd factor occurred, photo voltaic molding “did not fail.”

“We made some fairly low-quality elements at first, however we saved iterating, and by 2014 we have been molding high-quality plastic elements and had landed a number of essential patents,” stated Von Kries, who sees among the finest methods to make the most of SRM expertise as furnishing rural areas in poor international locations with essential plumbing gear like pipes and rainwater catch tanks.

MORE GREAT ENTREPRENEURIALISM: Ghanaian Lady Entrepreneur is Revolutionizing Transportation–Constructing Electrical Bikes to Enhance Air High quality

“At the moment our greatest system, the SRM4, can mould tanks as much as 2,000 gallons / 7,500 liters. Every system can mould hundreds of tanks a yr… and naturally, smaller tanks may be molded as properly.”

The mould system is fitted on a rotational axis inside a transport container, together with all management panels and electrical elements. No basis or base is required aside from one single acre of flat, cleared floor.

MORE FIELD MANUFACTURING:New Coloration-Altering Coating Impressed by Chameleons ‘May cool and heat buildings cheaply all yr spherical’

“All prices accounted for, our programs are one-tenth the price of deploying a conventional molding system in a manufacturing unit constructing,” Von Kires says.

With only a two-person crew, working prices are very low, whereas completed product price is 20-30% lower than merchandise made with conventional means as a result of the system doesn’t require pure gasoline for heating.

At the moment, Von Kries and Gentle Manufacturing have a system deployed already in Hawaii.

WATCH the system in motion…

WATCH This Superior Photo voltaic Powered Innovation With Your Pals…